Client

Requirement

Asian Paints is a leading paint manufacturer and supplier with a strong presence in the Indian market. The company is known for its high-quality paints and coatings and commitment to innovation and sustainability.

As part of its ongoing efforts to improve efficiency and safety in its operations, Asian Paints was looking for a solution to monitor the temperature of bus bars. The company was looking for a wireless, non-intrusive solution that could easily integrate into its existing systems.

Challenge

Several challenges are associated with manually monitoring the temperature of bus bars:

- Time-consuming: Manual readings of bus bar temperatures would have required engineers to physically go to each bus bar, take a reading, and then record the data. This process can be time-consuming and would have made monitoring temperatures in real-time challenging.

- Manual readings are subject to human error, which can lead to inaccurate data. Engineers may need help reading the temperature accurately or accidentally recording incorrect data.

- Engineers would have to be near the bus bars to take manual readings, which can pose a safety hazard if the bus bars operate at high temperatures.

- With Limited data collection, it would be challenging to identify trends or patterns in the bus bar temperatures.

- With manual readings, monitoring bus bar temperatures at remote locations or in different facilities would be challenging.

solution

To address this challenge, Asian Paints partnered with Bridge things to implement a wireless temperature monitoring solution. The solution was designed to address the challenge of manual reading of bus bar temperatures, which was time-consuming and error-prone.

With the implementation of temperature monitoring solutions consisting of wireless contact temperature beacons (with a coin cell battery life of up to five years), BLE LoRaWan bridge, LoRaWan GateWay, along with IoT platform

Wireless contact temperature beacon: The wireless contact temperature beacons were attached to the bus bars and could measure the temperature in real-time. It uses Bluetooth technology to wirelessly transmit the temperature data to a nearby Bluetooth to LoRaWAN converter.

Bluetooth to LoRaWAN converter: This device receives temperature data from the sensor via Bluetooth and transmits it to a LoRaWAN gateway using the LoRaWAN protocol. It is designed to receive temperature data from up to 10 sensor beacons and transfer it to LoRaWAN gateways.

The LoRaWan converter is essential in a temperature monitoring system, as it allows users to access and track temperature data from multiple sensor beacons remotely. Its Bluetooth and LoRaWAN capabilities enable it to connect to a wide range of sensors and gateways, making it a flexible and scalable solution for various applications.

LoRaWAN gateway: This device receives temperature data from the converter and transmits it to the cloud system using a cellular connection.

LoRaWAN gateway is a device that enables communication between end devices and a network server, allowing data to be transmitted over long distances with low power consumption. It can then be processed and made available to end-users through an IoT Platform.

IoT platform

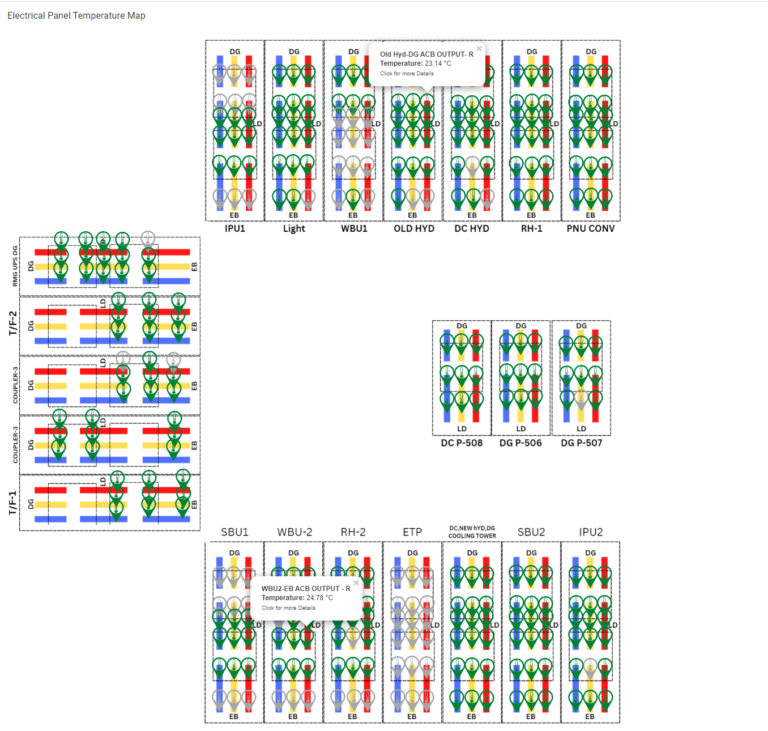

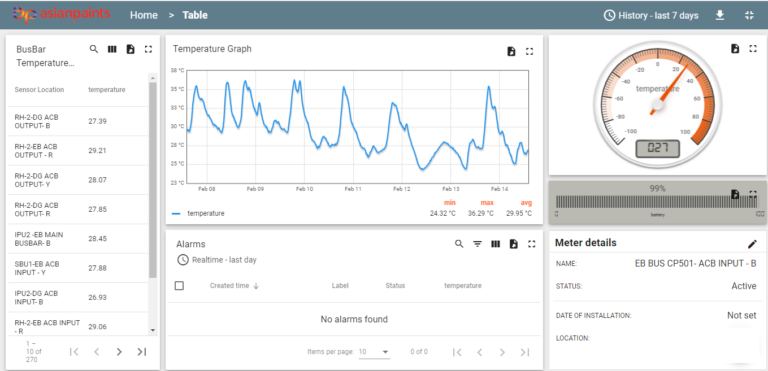

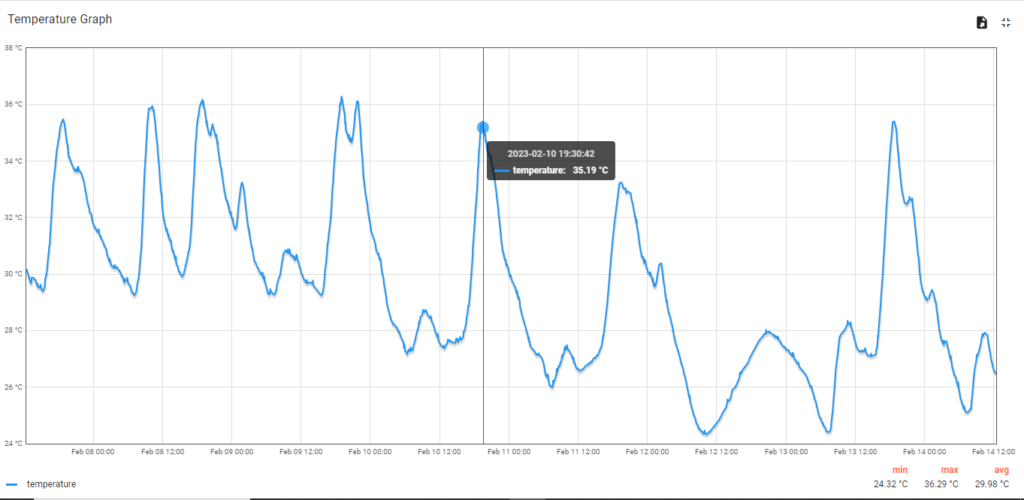

Our IoT platform provided real-time monitoring, allowing the company to quickly detect and address any issues with the bus bars. It also allowed for remote access, enabling engineers and managers to monitor the bus bars from anywhere at any time. Additionally, the platform provided advanced data analysis and visualization, which helped Asian Paints to identify patterns and trends in the temperature data and optimize its operations. It also included the ability to set alarms for specific temperature thresholds and generate reports for analysis, which helped to minimize the risk of damage to equipment or other safety hazards.

Benefits

- Improved efficiency: By monitoring the temperature of bus bars in real-time, Asian Paints was able to quickly detect and address any issues, which helped to improve the efficiency of its operations.

- Increased safety: The solution included setting alarms for specific temperature thresholds, which helped minimize the risk of damage to equipment or other safety hazards.

- Remote access: The IoT platform allowed engineers and managers to access temperature data remotely, which provided greater flexibility and allowed them to monitor the bus bars from anywhere at any time.

- Scalability: The dashboard was able to accommodate a large number of devices and sensors, making it possible to monitor multiple bus bars at once.

- Data analysis and visualization: The platform provided advanced tools for data analysis and visualization, which helped Asian Paints to identify patterns and trends in the temperature data and optimize its operations.